Uncategorized

FLUE ACCESSORIES

Flat Flashing

The flat flashing is the fire-resistant terminal element of the chimney flue that soaks up the inner tube with the outer coat of flue itself.

It is made of a base plate where is done a hole with an edge, on which is then assembled a tube that may have holes for the ventilation of the flue.

All the metal parts of the flat flashing are made of steel thk. 5/10 AISI 304 BA.

Air intake

This article is made to be installed outdoors in correspondence to the boiler air intake.

It may be equipped with its collar, to seal the hole in the wall where the pipe passes.

The product is produced in the following materials: AISI 304 BA.

Condensation exhaust

The condensation exhaust is the element installed at the bottom part of the flue to gather the acid condensates deriving from the flue. It is composed of one piece to which a threaded sleeve for the discharge of the condensate is connected and it is made of stainless steel AISI 316L BA.

It can be supplied in copper only in the plug enclosure version.

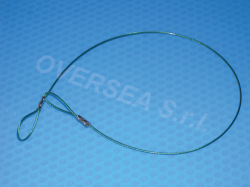

Steel Cable

Steel cable in coated steel wire with looped ends to anchor our round plug to the flue firmly.

Insert one of the end into the external part of the plug between its cover and the handwheel and/or handle, inserting the closed ring into the threaded pin, and the other end onto an anchor fixed on the flue itself.

Round cover for plastic chimney flue

Round cover for plastic chimney flue

This product is designed to be installed in flues with high rates of condensate where there is a T tube union, so as to allow inspection.

The round plug is composed of two elements, one outside, covering the pipe, the other inside, going into the pipe itself.

Between the two elements there is a silicone seal. This seal is temperature and condensate for GAS resistant, temperature class T140, homologated by the IMQ AT15S0479252-03 of 01/12/2015, according to EN14241-1:2013 standard.

This seal, under compression by means of an eccentric handle or handwheel, expands when getting on contact with the internal surface of the pipe. This creates a sealing effect against the smokes passing through the flue and the condensates inside it.

If necessary, the compression of the seal can be modified by means of a threaded pin integrated in the handle or handwheel.

The product is made of the following materials:

– Metal parts: sp. 10/10 AISI 304 BA – AISI 316L 2B or copper: Cu DHP UNI 5649/1

– Handle or handwheel: of moisture and weather-resistant plastic with temperatures between -20°C and + 240°C.

Round cover high temperature resistant

Round cover high temperature resistant

This product has been designed to be used for flues with operation temperatures higher than 200°C and up to 700°-800°. It is to be installed on a T pipe union, so as to allow inspection.

The round plug is made of two elements, one, outside, covers the pipe and the other, inside, goes into the pipe itself.

Between the two elements there is a metal seal AISI 302/316 with a heat-insulating jacket of ceramic fibre to insulate heat of the external element.

This seal, under pressure by means of an handwheel, expands and gets on contact with the internal surface of the pipe, thus creating that sealing effect against smokes passing trough the flue.

If necessary, the seal pressure can be modified by means of a threaded journal integrated in the handwheel.

The product is made of the following materials:

– Metal parts: sp. 10/10 AISI 304 BA – AISI 316L 2B or copper: Cu DHP UNI 5649/1

– Handwheel: AISI 303

In both steel and copper versions, on request the internal plate is available in AISI 316L 2B

Round cover low temperature resistant

Round cover low temperature resistant

This product is designed to be installed in flues with high rates of condensate where there is a T tube union, so as to allow inspection.

The round cover is composed of two elements, one outside, covering the pipe, the other inside, going into the pipe itself.

Between the two elements there is a silicone seal. This seal is temperature and condensate for GAS and GASOIL resistant, temperature class T200, homologated by the IMQ -AT15S0479252-01 del 03/07/2015, according to EN14241-1:2013 standard.

This seal, under compression by means of an eccentric handle or handwheel, expands when getting on contact with the internal surface of the pipe. This creates a sealing effect against the smokes passing through the flue and the condensates inside it.

If necessary, the compression of the seal can be modified by means of a threaded pin integrated in the handle or in the handwheel.

The product is made of the following materials:

– Metal parts: sp. 10/10 AISI 304 BA – AISI 316L 2B or copper: Cu DHP UNI 5649/1

– Handle or handwheel: of moisture and weather-resistant plastic with temperatures between –20° C and + 240°C.

In both steel and copper versions, on request the internal plate is available in AISI 316L 2B

Manometer holder and smokes drawing

The manometer holder is composed of a base plate which allows the part to be fastened on the flue. On the flue there are two holes to which some collars are spot-welded. In the case of a double-surface flue they allow to overtake the insulation zone and get inside the flue.

The big hole is closed by a drilled plug to read the temperature of the manometer. It can therefore contain the manometer. The small hole, on the contrary, is closed by means of a blind plug. The clasps are mechanical.

Some seals that can resist up to + 200° Celsius guarantee a sealing effect against the smokes and the possible condensate of the flue. These seals are placed on the closing plugs and, if there is a manometer, under it.

All the mechanical parts are made of stainless steel sp. 10/10 AISI 304 BA or copper: Cu DHP UNI 5649/1.

Square key

The square key to open the inspection hatch is made of self-destroying plastic, “class V0”.

It is weather resistant and resistant to temperatures from -20° up to +120° Celsius.

Inspection hatch

The Inspection hatch is made of a structure working as a fastening base for the manhole on the flue. It is made of two surfaces.

The inside surface can be removed and works as a thermal insulator by means of a 6 mm thick heat-insulating jacket, made of a glassy fibre ecology that can resist up to 1000° Celsius.

The outside surface, fixed to the structure, works as a water and air sealing surface by means of a NEOPRENE seal, locks the internal surface inside the structure by means of a mechanical clasp.

All the metal parts of the Inspection hatch are made of steel sp. 8/10 AISI 304 BA or copper: Cu DHP UNI 5649/1.